In this month’s playbook, we expand on the application of Process Analytical Technology (PAT) in the cannabis product formulation industry. We will delve deeper into advanced PAT applications that optimize the manufacturing process for vape pens, terpene purification, and edible dose monitoring. We will also explore the potential benefits of integrating PAT with data analytics and automation technologies to enhance process efficiency and product consistency.

Advanced Vape Pen Formulation

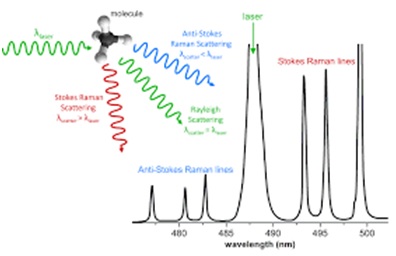

To further optimize the vape pen formulation process, incorporating Raman spectroscopy can provide valuable information on the molecular structure of the cannabis extract, carrier oil, and terpenes. This additional data enables manufacturers to fine-tune the formulation for optimal viscosity, stability, and bioavailability. Additionally, integrating PAT data with advanced process control (APC) software allows for real-time, automated adjustments during the formulation process, ensuring a more accurate and consistent final product.

Enhanced Terpene Purification

In addition to the PAT technologies mentioned last month, supercritical fluid chromatography (SFC) can be employed to further optimize terpene purification. SFC provides superior selectivity and efficiency in separating terpenes, enabling the isolation of target compounds with minimal degradation. Coupling SFC with mass spectrometry (MS) allows for real-time terpene purity and concentration analysis, providing valuable feedback for process optimization.

Advanced Edible Dose Monitoring

High-performance liquid chromatography (HPLC) can be integrated into the manufacturing process to further enhance edible dose monitoring. HPLC provides a more precise quantification of cannabinoids in the final product, ensuring a consistent dose. Combining HPLC data with advanced statistical process control (SPC) software allows manufacturers to identify and correct any deviations in the manufacturing process.

Editors’ Note: This is an excerpt from our Monthly Playbook. If you would like to read the full monthly playbook and join the thousands of others you can sign up below.